Air Locks (rotary valves) are the most commonly used feeding devices at pneumatic conveying lines. Air Lock consists of a rotor in a fixed housing. Rotary valves are ideally suited to both positive pressure and vacuum conveying lines. The rotary valve is also a positive displacement device and feed rate can be controlled by varying the speed of rotation.

Air-Locks are used in some processes as follows:

- To separate the air from product by placing the air lock under the cyclone or filter.

- To feed the product regularly into the pneumatic conveying line by blow-through type of air lock.

- To discharge the depots and silos regularly.

Pneumatic conveying plants can also work with negative pressure using blow-through air locks. Housing is made of cast-iron, rotor is made of steel, if required surface hardening can be done.

Where air-locks are employed?

Air-Lock Performance Table

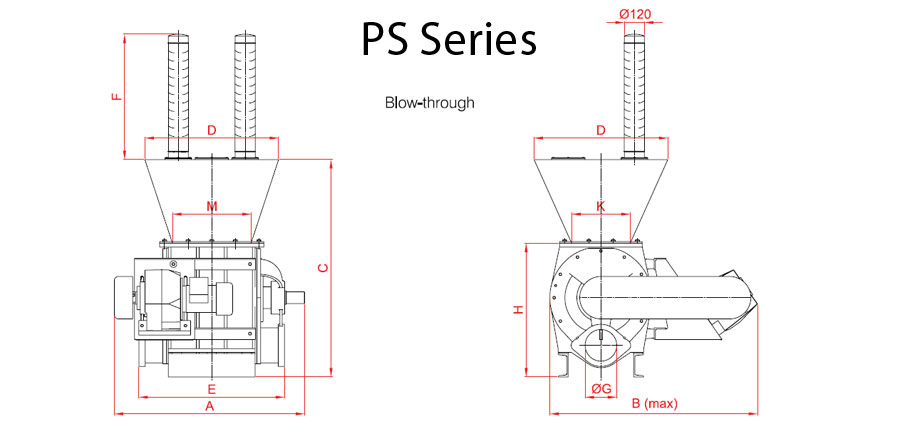

| Model | A | B (max) | C | D | E | F | ØG | H | K | M | Volume (lt/rev) | El.Mot. (kW) | Weight (kg) |

| PS 22/22 | 525 | 667 | 662 | 360 | 408 | 750 | 83 | 387 | 170 | 200 | 6 | 0,55 | 134 |

| PS 28/30 | 657 | 820 | 830 | 460 | 532 | 750 | 102 | 480 | 220 | 270 | 12 | 1,1 | 270 |

| PS 36/38 | 750 | 915 | 905 | 590 | 657 | 750 | 133 | 555 | 255 | 350 | 27 | 1,5 | 385 |

| PS 50/53 | 1138 | 1240 | 1300 | 800 | 871 | 1500 | 190 | 800 | 354 | 486 | 77 | 3 | 830 |

| PS 65/70 | 1523 | 1590 | 1816 | 1200 | 1134 | 1500 | 250 | 1016 | 460 | 640 | 180 | 4 | 1500 |

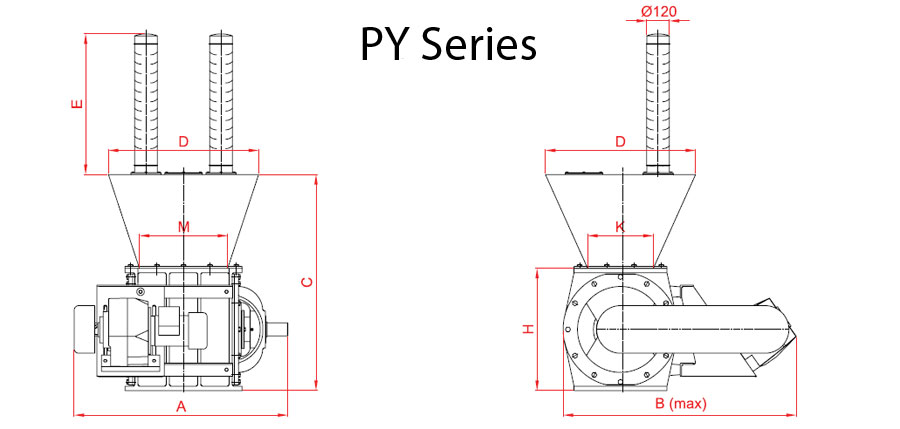

| Model | A | B (max) | C | D | E | H | K | M | Volume (lt/rev) | El.Mot. (kW) | Weight (kg) |

| PY 22/22 | 525 | 667 | 595 | 360 | 408 | 320 | 170 | 200 | 6 | 0,55 | 80 |

| PY 28/30 | 657 | 820 | 760 | 460 | 532 | 410 | 220 | 270 | 12 | 1,1 | 180 |

| PY 36/38 | 750 | 915 | 820 | 590 | 657 | 470 | 255 | 350 | 27 | 1,5 | 275 |

| PY 50/53 | 1138 | 1240 | 1160 | 800 | 871 | 660 | 354 | 486 | 77 | 3 | 785 |

| PY 65/70 | 1523 | 1590 | 1625 | 1200 | 1134 | 850 | 460 | 640 | 180 | 4 | 1400 |