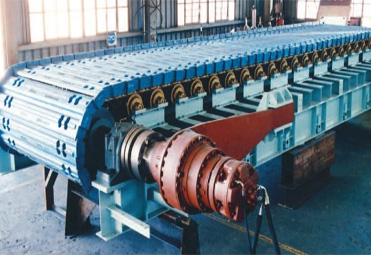

Apron feeder (also known as a pan feeder) is a mechanical type of feeder used in material handling operations to transfer (feed) material to other equipment or extract material (ore/rock) from storage stockpiles, bins or hoppers at a controlled rate of speed.

Apron Feeders are used to transport various types of bulk and part materials horizontally or slopingly. These displacers are divided into two types, light and heavy duty. In the heavy duty type, it is especially preferred to feed the crushers under the truck discharge bunkers. In addition to these, bunkers fed by a loader or a train are also located below, allowing the material to be taken in a dose.

An apron feeder, or plate conveyor renders one of the most superior conveying technologies for sharp-edged or high-density materials that have a significant impact when landing from height on the conveyor surface.

Applications:

- Dosing of products difficult to extract like clay, wet plaster, refinery waste, etc.

- Dosing of high temperature products like clinker at the gate of the kilns.

- Dosing of products with big particle size.

- Extractions of materials from quarry, feeding to the crusher, etc.

Advantages of Apron Feeders:

- Aprons provide better feed control to prevent material feeding in downstream equipment from choking,

- They can absorb the shock of loading material directly onto the feeder with a shallow bed (the impact coming down on the feeder when the material is dumped is great),

- Apron feeders can reclaim a variety of dry or wet materials of various sizes at a uniform rate, with this flexibility applied in many applications.

Apron feeders do have limitations when it comes to the size and type of ore. The limitations will vary, but there should never be senseless dumping of material onto the feeder. You will need to not only factor in the application you will be using the feeder for, but also where in the process this feeder will be placed.

Parts of Apron Feeder