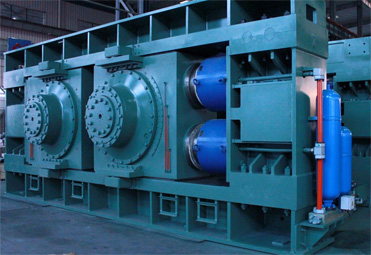

This machine is applied mainly for clinker but is also used for raw material and slag. The size reduction of the material takes place under high pressure between two rotating rollers. The machine can be installed in combination with a ball mill or as a finish grinding system.

Roller press is often used where energy-efficient grinding of large product quantities is required. The two rollers, rotating in opposite directions, exert very high pressure on the material, effectively crushing and weakening the particles (microscopic cracks), so that the subsequent fine grinding is easier. When used as a pre-grinding system in ball mill circuits, production increases of up to 100% and more can be achieved.

Rollers rotating is achieved by hydraulic/pneumatic supporting system and keeps roller gap or pressure constant. Each roller is driven by an electric motor through a gear reducer. The products discharged from roller press are compacted cakes of irregular size.

Its working principle is that bulk material is fed to the gap between two rollers which are driven in counter-rotation. The necessary press froce is provided by a hydraulic-pneumatic system which works like a spring. The feed material is compressed from the bulk density to 70-85 % of the real density and the individual particles are exposed to very high pressure. Comminution takes place in the packed material bed rather than through direct contact with the rollers. This reduces the wear of the grinding tools in comparison to conventional grinding methods.

Due to the unaxial grinding stress, the product shows a substantial amount of completed and incipient cracking emanating from the particle surfaces. Additionally, the particles usually exhibit micro-fractures and other defects which facilitate subsequent grinding and improve the kinetics of leaching, flotation or other separation processes.

Wear on a roller press mainly occours in the feed chute on the roller surface and on the cheek plates. The wear rate depends on the feed material (abrasiveness, moisture etc.) and on the operating parameters of the press.