Stacker and reclaimer that are machines where used in bulk material storage. Stacker is used to pile bulk materials as cement, coal, clinker, limestone, ores, fertilizer etc in heavy industry areas.

The operation of building a pile is called “stacking,” and removing and relocating operations are called “reclaiming.” Stackers and reclaimers are specialized for their respective operations, but a stacker-reclaimer is capable of handling both. This system is indispensable at ironworks, power plants, ports, and mines.

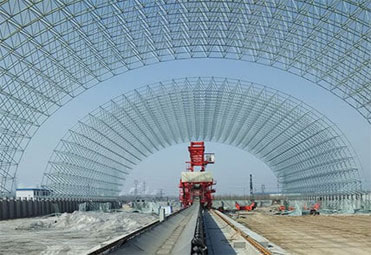

Stackers are nominally rated for capacity in tonnes per hour (tph). They normally move on a rail between stockpiles in the stockyard. A stacker can usually move in at least two directions: horizontally along the rail and vertically by luffing (raising and lowering) its boom. Luffing of the boom minimises dust by reducing the distance that material such as coal needs to fall to the top of the stockpile. The boom is luffed upwards as the height of the stockpile increases. Some stackers can rotate the boom. This allows a single stacker to form two stockpiles, one on either side of the conveyor.

Reclaimers are volumetric machines and are rated in m3/h (cubic meters per hour) for capacity, which is often converted to t/h (tonnes per hour) based on the average bulk density of the material being reclaimed.

Stacker-reclaimer is mostly preferred system material handling in mining, cement, coal, grain and etc. area.